Description

Moulds make the molten steel pour into cool fast, and solidify to blank with some thickness of shell. It is the most key part.

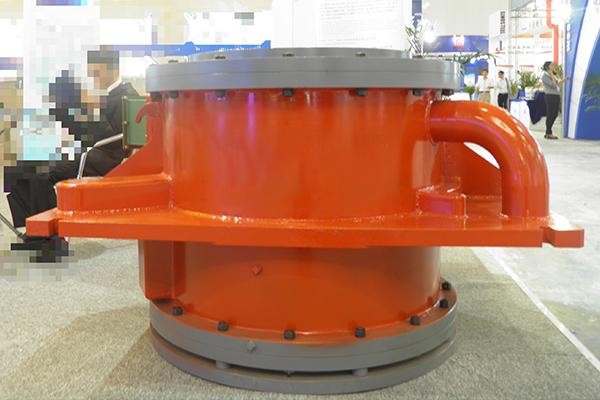

Mould is made from water wrap, leading water-flow wrap, copper pipe.

Water wrap is the structure weld jointed by steel plate, mould cooling water pass in and out water pipe .And the mould and vibration device aim at the joint support board to fix copper pipe and upper flange for lubricant, lower flange for orientation of copper pipe and support foot roller, protective board etc.

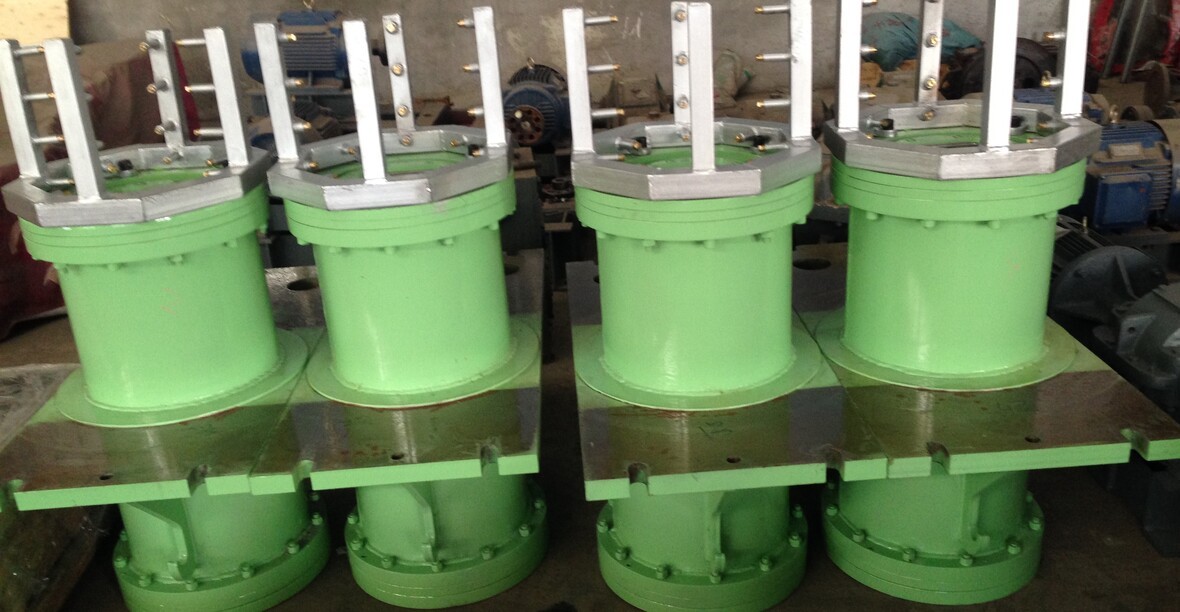

Leading water-flow wrap is machine-processed inside wrap for assuring the high speed of cooling water flow in the water slot outside the copper pipe and cooling the copper pipe uniformly.

The copper pipe is arc type with parabola cone-shaped degree, and sealed with sealing part, and clipped over the water wrap by upper flange. The lower flange orientates copper pipe to allow copper pipe expanding freely.

The mould bottom with sprayer tube device , its used for making the begaining billet cooled from the mould.